MODULAR Anti-Torsion Clip

MODULAR Anti-Torsion Clip

MODULAR Anti-Torsion Clips are specifically designed for RTA furniture and case goods. They are made of spring steel and come in two widths for 1/2″ and 3/4″ + material. By utilizing two spring steel clips, one male, and one female, the connectors simply slide into one another, preventing the joint from rotating. MODULAR Anti-Torsion clips work especially well in areas where only one clip can be used, such as a table apron as little as 2″ tall.

The MODULAR system was developed to join panels securely together in a fast and simple method with no visibility of the connector. The MODULAR 4030 Series Fastening System meets the objective by utilizing a spring steel declining ramp “clip” and a large collared Shoulder Screw at the two mating members. Spring steel makes the joint strong, yet flexible, while the collar on the Shoulder Screw adds tremendous resistance to torsional pull-out. Assembly occurs by simply sliding the Shoulder Screw head down the clips ramp. With the clip located in its pocket, and the system assembled, all fasteners disappear.

MODULAR come in Single Clips, Double Clips, and Anti-Torsion Clips. The MODULAR Double Clip Connector is unique, in that it makes two points on contact in a single connector, thus cutting down on installation time. With two spring steel ramps, not only is this an anti-rotating connector, but it also comes in different combinations of clips. i.e. one non-locking (4039) and one locking (4038)

We have 3 types of clips available: non-locking (easy to disassemble), semi-locking (hard to disassemble), and locking (cannot be disassembled). MODULAR comes in two widths, working with both 5/8″ and 3/4″ + material.

| Applications | Frames, chairs, furniture, cabinets, bookcases and shelving with heavy loads, fittings |

| Advantages | No rotation, concealed, self-tightening connector for 32 mm system, demountable |

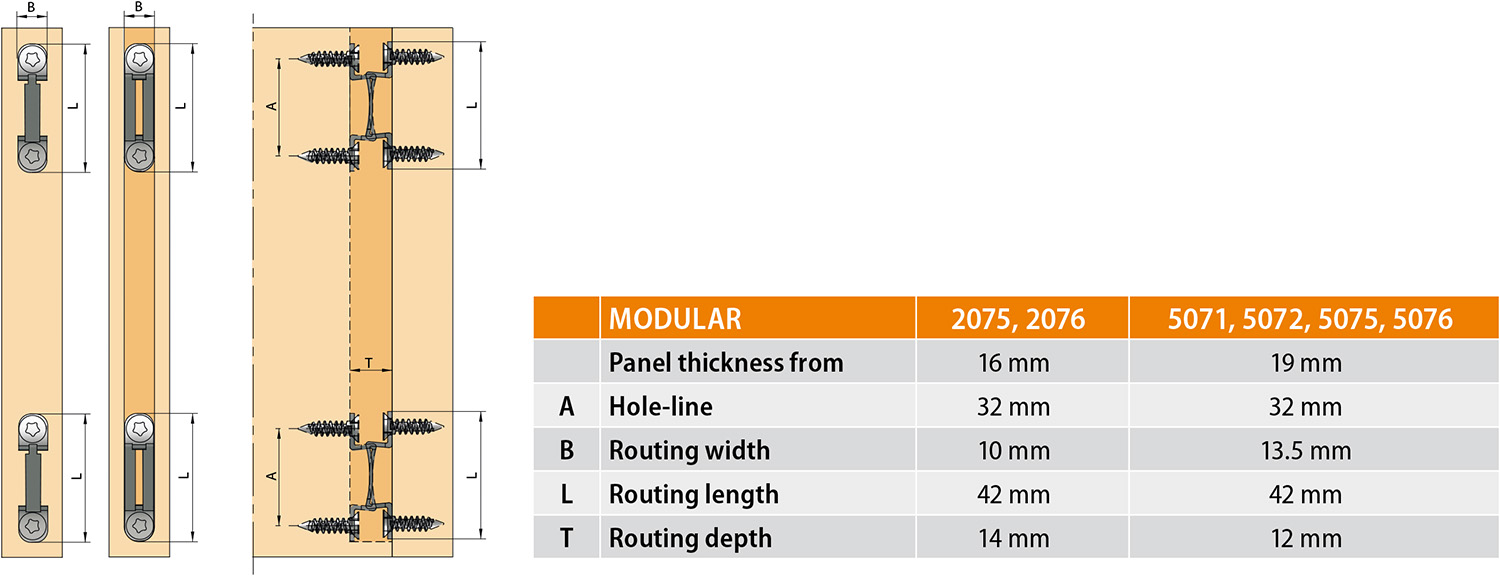

| Suitable materials | For all solid wood, wood based panels and plastic materials from 16 mm thickness up |

| Installation | Make groove with spindle moulder, horizontal router table, CNC equipment |

| Mounting | Pre-drill with drill-jig and install clips with PH or CS-screws Ø 4.5 mm (length depending on application) |

Fast assembly

- Efficient and very good to use in production line manufacturing

- Components are simply hooked together in seconds

- Reduces labor and equipment cost

- Efficient: High degree of pre-manufacturing

- Components can be transported and simply assembled on site

Non-visible connector

- Appeals to the architect and customer

- Concealed

Self-tightening

- The pass-thru, non-locking and semi-locking clips can be disassembled and reassembled

Versatile

- For materials from 16 mm thickness and up

- Used with all solid and wood-based materials and plastic as well as steel and aluminum

- 4 types of clips: Pass-thru, non-locking, semi-locking, and locking

Durable and Strong

- Spring steel sturdy design

- Longer PH-screws (approx. 5 x 60), can significantly increase the strength of the connector

- Perfect for industrial manufacturing with CNC

- Welding MODULAR Clips to steel (i.e. approximately 16 ga.) can be accomplished by wire welding

- Pockets to receive connectors are normally routed into the edge of a panel but can be routed into the face when design so requires

- To prevent engaged members from rotating (without anti-rotation clips) attach the Shoulder Screw in the pocket and the clip on the surface

- For handheld routers, use our MODULAR Drilling and Depth Jig for a perfect installation every time

- Used with all wood and board materials

- frames

- chairs

- furniture

- cabinets

- bookcases and shelving with heavy loads

- fittings