Research and Workshop Building in Diemerstein

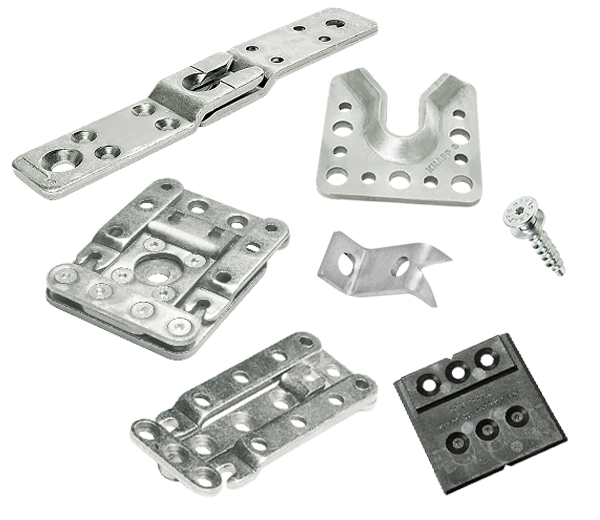

Knapp-Connector: WALCO® V60 / RICON® 100×40 EA / DA

Architect:

Design, Univ.-Prof. Stephan Birk (since April 2021 TU Munich), Marcel Balsen, Nik Beiler

Structural planning: planning and materials, Univ.-Prof. Dr.-Ing. Jürgen Graf, Reiner Klopfer, Viktor Poteschkin, Yannick Braun, Oliver Betha

Manufacturing three-hinge frames and cone adapters Schmeing GmbH & Co. KG, 57399 Kirchhundem, www.dehonit.de

Structural planning:

t-lab wood architecture and wood materials, fatuk, Rhineland-Palatinate Technical University Kaiserslautern-Landau (RPTU), 67663 Kaiserslautern, www.tlab.architektur.rptu.de

Builder:

Production of timber frame : Wilch Holzhaus GmbH

Manufacture of three-hinged frames: Schmeing GmbH & Co. KG

Machining wood: Cltech GmbH & Co. KG

Contractor:

Foundation TU Kaiserslautern, Administration Dr. agr. Annette Mechel, 67663 Kaiserslautern, www.rptu.de

t-lab wood architecture and wood materials, fatuk, Rhineland-Palatinate Technical University Kaiserslautern-Landau (RPTU), 67663 Kaiserslautern, www.tlab.architektur.rptu.de

Engineering:

Drees & Sommer Advanced Building Tech. Stuttgart

Ralf Buchholz

Fire protection consulting:

IBC Engineering-Consult GmbH Mainz

Martin Hermes

Geotechnical report:

Jörg Huber Engineering Office

Dipl.-Ing. J. Huber

Year of construction: 2022

Construction method:

Construction (e.g., glulam wall and roof)

Structural System: Three-hinged frames made of BauBuche (bars) and synthetic resin-bonded wood (nodes)

Wooden frame and Insulation layer

Address: Diemerstein 6, 67468 Frankenstein, Germany

Building space: approx. 360 m²

Image sources: t-lab/Technische Universität Kaiserslautern, Andreas Labes

Video

HUF Haus - WALCO® V

Project: HUF Haus ART 3

Knapp-Connector: RICON® S and WALCO® V

Architect: Josef Günster

Planning: HUF HAUS

Timber construction: HUF HAUS

Builder: Private client

Year of construction: 2020

Duration of construction: About 2 weeks for construction of the building

Method of construction: Modern half-timbered architecture with glued timber framework construction

Gross building volume: 219 m²

Housebuilding – Riedpark in Lauchringen (D)

Project: Residential and commercial real estate in Riedpark / Lauchringen (D)

Knapp-Connector: WALCO® V and RICON® S

Architect: Jörg Kaiser Architekturbüro, Hauptstr. 47, 79787 Lauchringen, www.architektkaiser.de

Structural engineering: Lignotrend Produktions GmbH, Landstr. 25, 79809 Weilheim-Bannholz, www.lignotrend.de

Timber construction: Holzbau-Amann GmbH, Albtalstr. 1, 79809 Weilheim-Bannholz, www.holzbau-amann.de

Jonathan Loderbauer, Kapellenstr. 3, 79737 Herrischried, www.die-holzerei.de

Holzbau & Zimmerei Maise, Stiegstr. 27, 79774 Albbruck-Unteralpfen, www.holzbau-maise.de

Year of construction: 2017

Address: 79787 Lauchringen (BW)

Press release: Südkurier vom 16.02.2017

Stalls with WALCO®

Project: Demountable stalls for the District Museum Association Schloss Landeck (AT)

Method of construction: Timber frame construction

Knapp-Connector: WALCO® V

Timber construction: Students of the HTL Imst with Ing. Dipl.-Päd. Gerhard Peer HTL Imst / Building Technology Department, www.htl-imst.at

Architect: HTL Imst / Building Technology Department

Housebuilding – Single-family houses and urban villas (AT)

Project: Prefabricated houses (AT)

Method of construction: Frame construction

Knapp-Connector: WALCO® V

Timber construction: Genböck Haus Genböck & Möseneder GmbH, www.genboeck.at

Architect: Genböck Haus Genböck & Möseneder GmbH

Energy usage: For example passive houses, energy-plus-houses

Housebuilding – Addition of storeys to a multi-family house (DE)

Project: Addition of storeys to a multi-family house (DE)

Knapp-Connector: WALCO® V

Builder: Braintec GmbH, 83132 Pittenhart, www.brain-tec.net

Architect: ARCHITEKTURBÜRO ANSELM KANNO, www.architekt-kanno.de

Timber constructor: Zimmerei Holzbau – Schröder, www.holzbau-schroeder.com

Structural engineering: Andreas Reinicke, 21354 Bleckede

Method of construction: Timber frame construction

Construction time: 8 months

Press article: mikado 5/2014

Housebuilding – House^3 (US-MN)

Project: Prefabricated house – House^3 (US-MN)

Knapp-Connector: WALCO® V

Builder / Project developer / Architect: University of Minnesota Duluth, www.d.umn.edu

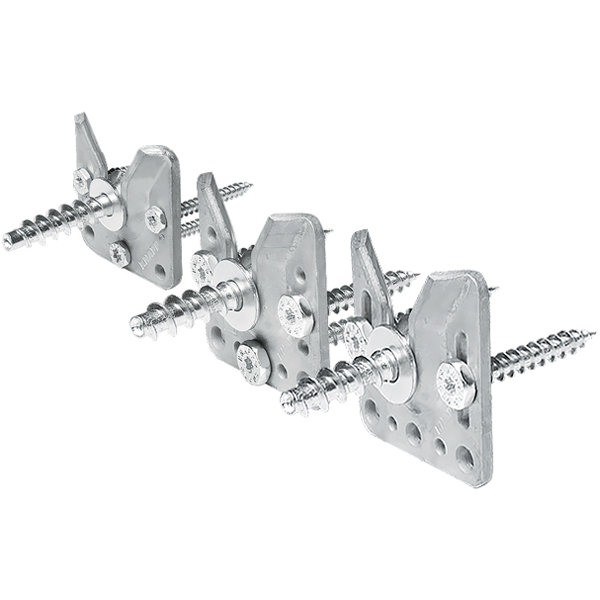

Details: The most unique characteristic of House³ is its ability to be transported, assembled, disassembled, and redeployed. House³ uses proprietary wall connectors to ensure that prefabricated wood framewalls can be slid into place directly on site with minimal effort. Most importantly, the connectors allow for a clean disassembly and repacking of the module for relocation.

Brochure: Containerhäuser USA

Housebuilding – New constructed housing complex in Sistrans (AT)

Project: Prefabricated house – Housing complex in Sistrans (AT)

Knapp-Connector: WALCO® V

Architect: Teamk2 (Architects), www.teamk2.com

Timber construction: Schafferer Holzbau, www.schafferer.at

Press article: mikado 3/2011

Housebuilding – Wooden four-storey building in Bad Aibling (DE)

Project: Prefabricated four-storey building in Bad Aibling (DE)

Knapp-Connector: WALCO® V

Builder: B&O-Gruppe Bad Aibling, www.bo-wonungswirtschaft.de

Planning: SCHANKULA Architekten/Diplomingenieure, www.schankula.com

Timber construction: Huber & Sohn GmbH & Co. KG, www.huber-sohn.de

Press article: mikado 10/2010

“Mc Cube” – Modular house to put together

Project: Modular house to put together / Winklarn (AT)

Knapp-Connector: WALCO® V

Builder: Martina Kies

Architect: Mc Cube Homes GesmbH iG, www.mccube.at

Timber constructor: Fahrenberger GmbH, www.zimmerei-f.at

Finalized: Autumn 2014

Press article: momag 326 | November 2014

Housebuilding – international competition “Solar Decathlon Europe 2010”

Project: Prefabricated houses for the Solar Decathlon Europe 2010 – 2nd place in the overall ranking (ESP)

Knapp-Connector: WALCO® V, RICON®, QUATRO 65

Builder/Project developer/Architect: TEAM IKAROS BAVARIA | FH Rosenheim, www.solar-decathlon.fh-rosenheim.de

Details: It remained exciting until the end: on the evening of the last competition day of the first international university competition „Solar Decathlon Europe 2010“ on European soil, the 17 participant teams came together for the award ceremony. Richard King, the inventor of the „Solar Decathlon“ in the US, welcomed the Decathletes. Then the winners were determined: Rosenheim took the second place – for the outstanding performance of the student „Team IKAROS Bavaria“ of the University of Applied Sciences – University of Applied Sciences Rosenheim.

Brochure: Solar Decathlon Europe 2010

Housebuilding – Nine housing units in a backyard (GBR)

Project: Prefabricated houses – Nine housing units in a backyard, London-Harlesden (GBR)

Knapp-Connector: WALCO® V, WALCO® 40

Builder / Project developer / Architect: SUSD Ltd., www.susd.co.uk

Structural engineering: Dr. Dubslaff & Rosenkranz D-59939 Olsberg, www.rdr-energie.de

Timber construction: Holzbau Becker & Sohn GmbH, Kolpingstraße 4, 59964 Medebach, www.becker360.de/referenzen/wohnhaeuser

Construction time: December 2008 – December 2010

Method of construction: Wooden frame and plank pile design

Gross building volume: 2342 m³ / 897 m²

Press article: mikado 12/2010

Brochure: Referenzprojekt Urbaner Holzbau London